Schatten uit koninklijke tuin

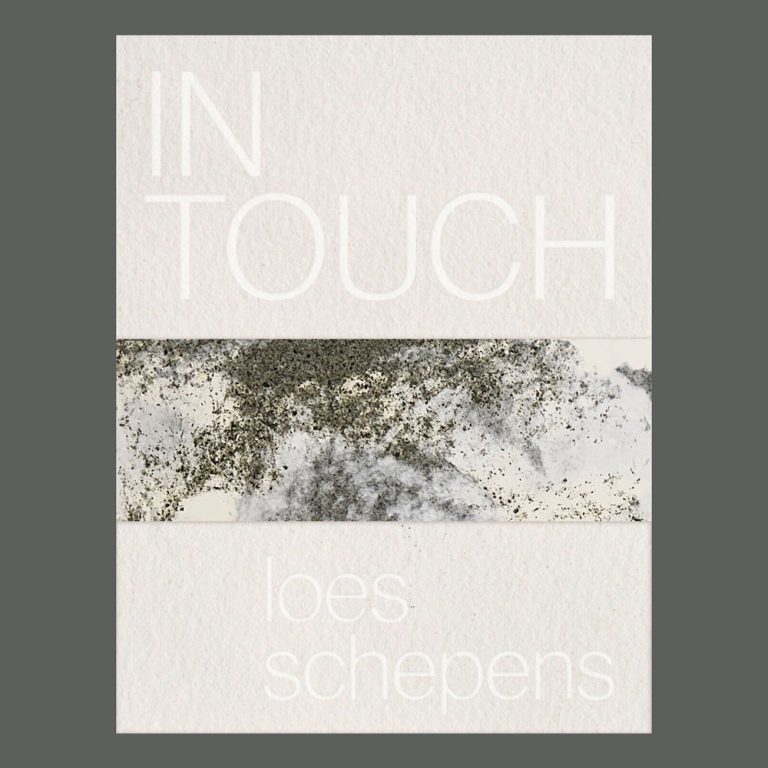

De 6 kunstenaars van het Botanical Tales collectief mochten een jaar lang inspiratie opdoen en materiaal verzamelen uit de tuin van Paleis Soestdijk. De werken die Loes Schepens maakte zijn nu te zien bij Paper Art & Design.

5 mei t/m 8 aug 2025